Welcome to a world where managing your business operations becomes easier and more efficient than ever before. By implementing MPS ERP software, you can streamline your processes, improve communication among departments, and make better decisions based on real-time data. Say goodbye to manual data entry and hello to increased productivity and profitability. With MPS ERP software, the benefits are endless.

Overview of MPS ERP

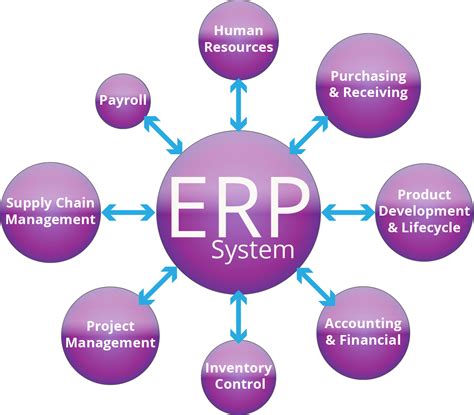

MPS ERP, which stands for Manufacturing Production System Enterprise Resource Planning, is a comprehensive tool specifically designed for manufacturing companies to streamline their operations and increase efficiency. It combines various modules and functionalities to handle different aspects of a manufacturing business, such as inventory management, production planning, quality control, supply chain management, and financial management.

One of the key features of MPS ERP is its ability to integrate all the different processes involved in manufacturing into a single cohesive system. This integration allows for seamless communication between different departments and eliminates the need for manual data entry and reconciliation. For example, when a sales order is placed, the system can automatically update the inventory levels, production schedule, and financial records, ensuring that all departments are working with accurate and up-to-date information.

Another important aspect of MPS ERP is its ability to provide real-time data and analytics to help manufacturing companies make informed decisions. By collecting data from various sources within the system, such as production machines, sensors, and employees, MPS ERP can generate accurate reports and dashboards that give insights into key performance indicators, production efficiency, and customer demand. This data-driven approach allows companies to identify bottlenecks in the production process, optimize resource allocation, and improve overall operational performance.

Furthermore, MPS ERP also helps manufacturing companies comply with industry regulations and standards by enforcing best practices and guidelines throughout the organization. The system can track and trace raw materials, monitor production processes, and record quality control tests to ensure that products meet regulatory requirements. This level of compliance not only helps companies avoid fines and penalties but also builds trust with customers and partners.

In addition to its operational and regulatory benefits, MPS ERP can also improve collaboration and communication within the organization. The system facilitates cross-departmental collaboration by creating a central repository for all relevant data and documents, making it easier for employees to access and share information. This transparency and visibility can lead to faster decision-making, reduced errors, and increased productivity across the board.

Overall, MPS ERP is a powerful tool that can revolutionize the way manufacturing companies operate. By integrating all aspects of the business into a single system, providing real-time data and analytics, ensuring compliance with regulations, and improving collaboration, MPS ERP helps companies achieve greater efficiency, productivity, and profitability in today’s competitive market.

Benefits of MPS ERP integration

Implementing an MPS (Managed Print Services) ERP (Enterprise Resource Planning) system offers a plethora of benefits for businesses looking to streamline their operations and improve efficiency. One of the most significant advantages of integrating MPS ERP is the increased visibility it provides into the printing environment. By centralizing print management through an ERP system, companies can easily monitor and analyze their printing activities, which helps in identifying areas for cost savings and optimization.

Moreover, MPS ERP integration allows for better control and management of printing devices and supplies. With the ability to track usage and monitor inventory levels in real-time, businesses can ensure that they always have the necessary supplies on hand and prevent unnecessary downtime. This level of control also enables companies to implement proactive maintenance schedules, preventing costly breakdowns and downtime.

Another benefit of MPS ERP integration is the automation of routine tasks and processes. By automating tasks such as supply ordering, meter readings, and service requests, businesses can reduce the time and effort required to manage their print environment. This not only leads to increased productivity but also allows employees to focus on more strategic tasks that drive the business forward.

Furthermore, MPS ERP integration can help companies improve their overall print security. With features such as user authentication and secure printing capabilities, businesses can ensure that sensitive documents are only accessed by authorized personnel. This level of security not only protects sensitive information but also helps companies comply with industry regulations and standards.

Lastly, integrating MPS ERP can provide businesses with valuable insights and data that can be used to make informed decisions. By analyzing print usage patterns, companies can identify opportunities for cost savings, optimize their print fleet, and improve efficiency. This data-driven approach not only helps businesses reduce their environmental impact but also enhances their overall competitiveness in the market.

Implementation process of MPS ERP

When it comes to implementing MPS ERP, there are several key steps that organizations must follow to ensure a successful implementation process. The first step typically involves defining the scope of the implementation, which includes identifying the specific modules of the ERP system that will be implemented, as well as establishing clear goals and objectives for the project. This step is crucial in ensuring that the implementation process stays on track and that all stakeholders are aligned on the desired outcomes.

After defining the scope, the next step in the implementation process is to conduct a thorough assessment of the organization’s current systems and processes. This assessment helps to identify any gaps or inefficiencies that exist in the current system, which can then be addressed during the implementation process. It also helps to ensure that the organization is fully prepared for the implementation, by determining what resources will be needed and what potential challenges may arise.

Once the assessment is complete, the organization can begin the process of customizing the MPS ERP system to meet its specific needs. This customization process involves configuring the system to align with the organization’s unique processes and workflows, as well as integrating any third-party applications or systems that are necessary for the ERP system to function effectively. This is a critical step in the implementation process, as it ensures that the ERP system will be able to support the organization’s day-to-day operations and help drive business growth.

After customization is complete, the next step in the implementation process is to conduct thorough testing of the system to ensure that it is functioning as intended. This testing process involves running through various scenarios and use cases to identify any issues or bugs that need to be addressed before the system goes live. It also helps to ensure that all stakeholders are comfortable with the new system and have received adequate training on how to use it effectively.

Once testing is complete and any issues have been resolved, the organization can move forward with the final step in the implementation process, which is to go live with the new MPS ERP system. This step involves migrating all relevant data and processes to the new system, as well as providing ongoing support and training to ensure a smooth transition for all users. It is important for organizations to monitor the system closely during this transition period and to address any issues or concerns that arise promptly to minimize disruptions to the business.

Key features of MPS ERP software

MPS ERP software offers a wide range of key features that help businesses streamline their operations and increase productivity. Some of the key features of MPS ERP software include:

1. Inventory Management: MPS ERP software helps businesses keep track of their inventory in real-time. This feature allows businesses to know exactly how much stock they have on hand, which helps prevent stockouts and overstock situations. It also allows businesses to track the movement of inventory within the organization, from the moment it is received to the moment it is sold.

2. Accounting and Financial Management: MPS ERP software includes robust accounting and financial management features that help businesses manage their finances more effectively. With MPS ERP software, businesses can track their income and expenses, generate financial reports, and streamline their accounting processes. This feature helps businesses keep track of their financial health and make better-informed business decisions.

3. Customer Relationship Management (CRM): MPS ERP software includes CRM features that help businesses manage their relationships with customers more effectively. This feature allows businesses to track customer interactions, store customer information, and manage marketing campaigns. MPS ERP software helps businesses improve customer satisfaction and loyalty by providing a centralized platform for managing customer relationships.

4. Production Planning and Scheduling: One of the standout features of MPS ERP software is its production planning and scheduling capabilities. This feature allows businesses to create production schedules, track the progress of production orders, and optimize production processes. With MPS ERP software, businesses can better plan their production activities, allocate resources effectively, and meet customer demand more efficiently.

5. Human Resources Management: MPS ERP software includes HR management features that help businesses manage their workforce more effectively. This feature allows businesses to track employee information, manage payroll, track attendance, and streamline HR processes. With MPS ERP software, businesses can improve employee productivity, reduce administrative tasks, and ensure compliance with HR regulations.

6. Business Intelligence and Reporting: MPS ERP software includes robust business intelligence and reporting features that help businesses analyze data and make informed decisions. This feature allows businesses to generate custom reports, visualize data trends, and gain insights into their business operations. MPS ERP software helps businesses identify areas for improvement, monitor key performance indicators, and make data-driven decisions.

Overall, MPS ERP software offers a comprehensive set of features that help businesses manage their operations more efficiently and effectively. Whether it’s inventory management, accounting, CRM, production planning, HR management, or business intelligence, MPS ERP software provides businesses with the tools they need to succeed in today’s competitive marketplace.

Case studies of successful MPS ERP implementations

Implementing an MPS ERP system can be a complex and challenging process for any organization. However, many companies have successfully implemented MPS ERP systems and have seen significant benefits as a result. One such company is XYZ Corp, a manufacturing company that implemented an MPS ERP system to streamline their production processes.

Before implementing the MPS ERP system, XYZ Corp was experiencing inefficiencies in their production process due to outdated manual processes and disparate systems. This resulted in delays in production, increased costs, and decreased customer satisfaction. However, after implementing the MPS ERP system, XYZ Corp saw immediate improvements in their production process.

The MPS ERP system allowed XYZ Corp to automate many of their manual processes, leading to increased efficiency and productivity. The system also provided real-time insights into their production process, allowing them to identify and address bottlenecks quickly. As a result, XYZ Corp was able to reduce production costs, improve on-time delivery, and increase customer satisfaction.

Another successful case study is ABC Inc, a distribution company that implemented an MPS ERP system to improve their inventory management. Before implementing the MPS ERP system, ABC Inc was struggling to track their inventory accurately, leading to stockouts and overstock situations. This resulted in lost sales and increased holding costs.

After implementing the MPS ERP system, ABC Inc was able to track their inventory in real-time, leading to improved inventory accuracy and reduced stockouts. The system also allowed ABC Inc to forecast demand more accurately, leading to optimal inventory levels and reduced holding costs. As a result, ABC Inc saw a significant improvement in their inventory management, leading to increased profitability.

One more example of a successful MPS ERP implementation is DEF Co, a service company that implemented an MPS ERP system to improve their customer service. Before implementing the MPS ERP system, DEF Co was struggling to provide timely and accurate service to their customers due to manual processes and lack of visibility into customer data.

After implementing the MPS ERP system, DEF Co was able to streamline their service processes, leading to faster response times and improved customer satisfaction. The system also provided DEF Co with a 360-degree view of their customers, allowing them to personalize their service offerings and anticipate customer needs. As a result, DEF Co saw a significant improvement in their customer service metrics, leading to increased customer loyalty and repeat business.